Not long ago, Process Jun reported on the thousand ton Fischer Tropsch synthesis of Inner Mongolia Yitai Group α- The demonstration device for olefin separation and purification has been successfully launched in Ordos, and the article has been put into operation▼

The international first set in China! Thousand ton Fischer Tropsch synthesis α- The demonstration unit for olefin separation and purification has successfully started operation in Ordos

Construction project name and summary

Project Name: 100000 tons/year High end α Olefin project

Project Location: Wanhua Yantai Industrial Park, Yantai Chemical Industry Park, Shandong Province

Project Overview: Newly built 100000 tons/year high-end α Olefin production equipment and supporting public works and auxiliary facilities.

Construction unit: Wanhua Chemical Group Co., Ltd

Construction nature: New construction project

Overview of Enterprises in Wanhua Yantai Industrial Park

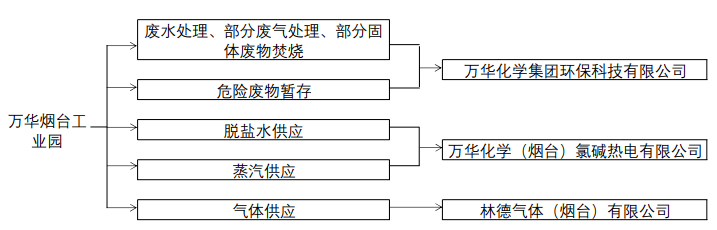

The project is located in Wanhua Yantai Industrial Park, Yantai Chemical Industry Park. The main enterprises in the park include Wanhua Chemical Group Co., Ltd., Linde Gas (Yantai) Co., Ltd., Wanhua Chemical (Yantai) Chlor-alkali Thermal Power Co., Ltd., Wanhua Chemical Group Environmental Protection Technology Co., Ltd., Wanhua Chemical (Yantai) Rongwei Polyurethane Co., Ltd., etc. Linde Gas (Yantai) Co., Ltd. provides nitrogen and air to Wanhua Chemical Group Company; Wanhua Chemical (Yantai) Chlor-alkali Thermal Power Co., Ltd. provides steam to Wanhua Chemical Group Company; Wanhua Chemical Group Co., Ltd., Wanhua Chemical (Yantai) Chlor-alkali Thermal Power Plant, and Wanhua Chemical (Yantai) Rongwei Polyurethane Co., Ltd. are mainly entrusted to Wanhua Environmental Protection Technology for treatment of wastewater, solid waste, and exhaust gas. Each company is independently managed and applies for a pollution discharge permit separately.

Schematic diagram of the supporting relationships between various branches of Wanhua Group

α- Overview of olefins

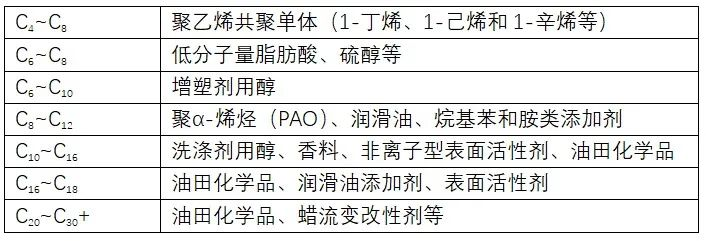

α- Alkenes are widely used, mainly in the synthesis of polyethylene. linear α- Olefins refer to straight chain monoolefins with double bonds located at the end of molecular chains. In industrial production, they usually refer to high carbon straight chain end olefins with C4+. Their main application areas are shown in Table 1.

Table 1 α- Main uses of olefins

Source: Ningxia Engineering Technology as a copolymer monomer for polyolefins α- Alkenes are mostly C4~C8 olefins, among which 1-butene, 1-hexene, 1-octene can be copolymerized with ethylene to prepare high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), and polyolefin elastomers (POE). They can also be copolymerized with ethylene and propylene to prepare propylene/ethylene/butene ternary random polypropylene, or copolymerized with propylene to prepare butene copolymer polypropylene, etc. Among them, those used for polyolefin copolymerization α- Olefins account for 70% or more of the total consumption scale. Project construction significance

high-end α- Alkenes (1-octene, 1-hexene) have low circulation and are in short supply in the market, making them widely used in Wanhua's existing production facilities. This product, relying on external procurement, has high costs, inconvenient transportation and service, and tight supply, which affects the stable operation of the device. Therefore, it needs to be high-end α- Construction of olefins (1-octene, 1-hexene). After the completion of this project, it can reduce a large amount of high-end products for Wanhua every year α- The cost of outsourcing olefins and reducing external constraints on the operation of production facilities to achieve stable supply of related raw materials.

The site of this project is located in Wanhua Industrial Park, with good social conditions to rely on, convenient transportation, and the use of existing public and auxiliary facilities in the factory area, which is conducive to accelerating project construction progress and reducing construction investment. The project adopts Wanhua's own technology, which is advanced in technology, low in consumption, guaranteed in technology, and implemented with measures.

recent α On July 12th, the Ecological Environment Bureau (Daishan Branch) of Zhoushan City issued a list of new developments in olefins for Zhejiang Petrochemical Co., Ltd α- Announcement on the approval decision of the environmental impact assessment report for the olefin plant project. On June 2nd, Satellite Chemistry replied on the investment platform that the company had independently developed α- The olefin industrial test facility has been running steadily and is planned to be completed in the second half of the year. α- The industrial facilities for olefins and POE are planned to start construction in the second half of the year and aim to be completed by the end of next year. Satellite chemistry's 1-octene is the first of its kind in China, and there is no production facility available domestically. On June 1st, the Ecological Environment Bureau of Zhanjiang City, Guangdong Province, approved the construction of Donghai Island by Zhanjiang Zhongjie Jingchuang Material Technology Co., Ltd. with an annual production capacity of 50000 tons/year α- The approval decision for environmental impact assessment documents for olefin, 100000 tons/year POE, and 200000 tons/year lithium-ion electrolyte projects will be made public. On May 30th, Yitai Chemical Co., Ltd. achieved a tonnage of 1000 tons α- The intermediate handover ceremony of the olefin pilot project was held at the site of the device in the southern project area of Dugui Tara Industrial Park in Hangjin Economic Development Zone. On May 19th, the Shenghong Refining and Chemical Olefin Industry Chain Project was registered. The project mainly includes 200000 tons/year α- Olefin unit, 300000 ton/year POE unit, 300000 ton/year butanol and octanol unit, 300000 ton/year acrylic acid and ester unit, and 240000 ton/year bisphenol A unit. On May 9th, the safety condition review of the 1000 ton/year 1-hexene and 300 ton/year 1-octene production facilities of Zhejiang Petrochemical Co., Ltd. was approved.